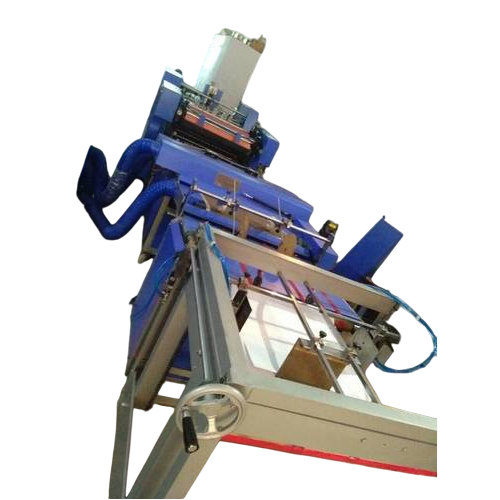

Offset UV Coater

Product Details:

Offset UV Coater Price And Quantity

- 750000.00 INR

- 1 Piece

- 750000.00 - 1500000.00 INR

Offset UV Coater Trade Information

- Cash in Advance (CID) Cheque

- Bubbles polybag

- Asia

- All India

Product Description

An offset UV coater is a type of machine used in the printing industry to apply a layer of ultraviolet (UV) coating to printed materials such as brochures, postcards, and catalogs.This process involves applying a thin layer of UV coating to the surface of the printed material using rollers or a spray system. The UV coating is then cured using UV light, which hardens the coating and gives it a glossy or matte finish, depending on the desired effect.The main advantage of using an offset UV coater is that it allows for high-speed coating of large volumes of printed materials with a consistent finish. The UV coating also provides additional protection to the printed material, making it more durable and resistant to scratches, scuffs, and fading.

FAQs

1. What is an Offset UV Coater?

An Offset UV Coater is a machine used to apply a coating of ultraviolet (UV) light-cured varnish to a printed sheet. This coating is cured almost instantly with UV light, providing a glossy and durable finish that can help protect the printed image.

2. What types of materials can be coated with an Offset UV Coater?

Offset UV Coaters can be used to coat a wide range of materials including paper, card stock, plastic, metal, and wood.

3. How long does it take for the UV coating to cure?

The curing time for UV coating depends on the size and thickness of the material being coated. Generally speaking, it takes just a few seconds for the coating to cure.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese