- Home Page

- Company Profile

-

Our Products

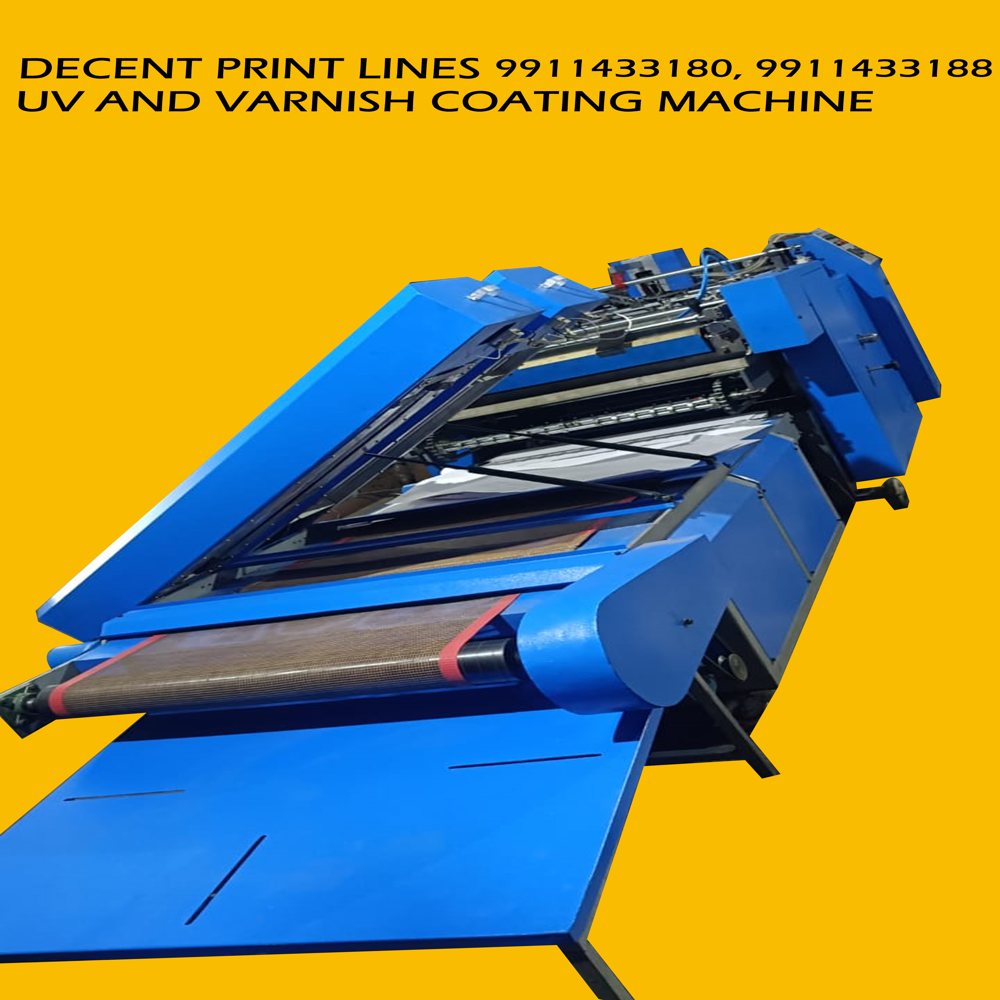

- UV Coating machinery

- Automatic UV coating Machine

- Automatic UV Coater

- Aqua Varnish Coating Machine Manual

- Fully Automatic UV Machine

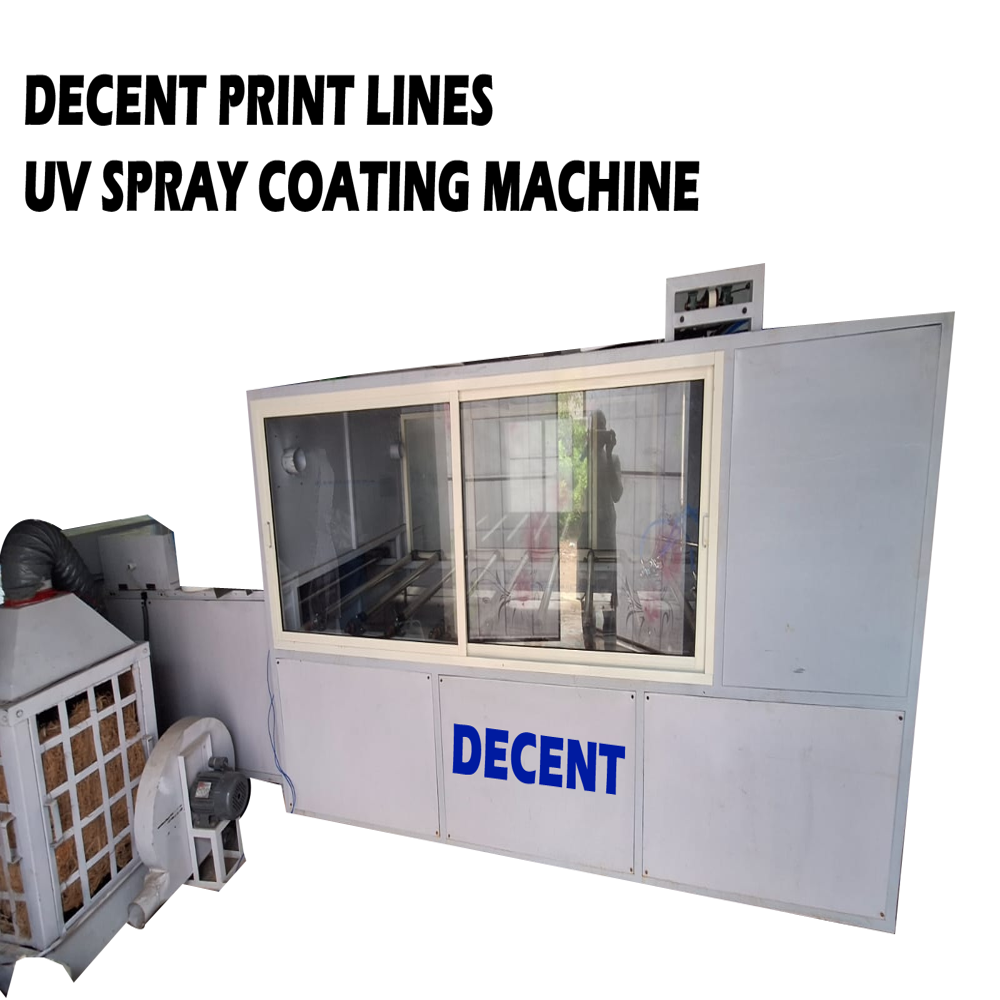

- Automatic UV Spray Coating Machine

- Fully Automatic UV Coating Machine

- Full UV Coating Machine

- Semi Automatic Aqueous and UV Coating Machine

- Offset UV Coater

- UV Coating and UV Curing Machine

- UV Coating and UV Dryer

- UV and Aqua Varnish Coating Machine Fully Automatic

- Aqueous Coating Machine

- INDUSTRIAL UV COATING MACHINE

- Manual UV Coater

- Flat Screen Printing

- UV Interduck machine

- UV Curing Machine

- Attachment Coater machine

- Poly Bag Printing Machine

- Non Woven Bag Printing Machine

- SUPER SOLNA MODAL PRINTING MACHINE

- Single Color Non woven Bag Printing Machine

- Multi Color Non Woven bag and Paper Printing Machine

- Non Woven Printing Machine

- Two Color Non Woven Bag Printing Machine 16X22

- Multi Color Offset Printing Machine With UV Dryer

- Cloth Bag Printing Machine

- Multi Color Offset Printing Machine Made In India

- Offset Printing Machine

- Automatic Non Woven Bag Printing Machine

- Double Color Non Woven Printing Machine

- Three Color Super Solna Heavy Duty Compact Model Offset Printing Machine

- Non Woven bag Printing Machines

- D-Cut Bag Printing Machine

- Double color Fabric Bag Printing Machine

- Three Color Non Woven Bag printing Machine

- Non Woven Bag Printing Machine Double Color

- Offset Carry Bag Printing Machine

- Paper Printing Machine

- UV Coating machinery

- Contact Us

Call us now08045479026